Glucose Powder Rotary Vibration Shaker

The glucose powder rotary vibrating screen used in the glucose production process is a new type of rotary vibrating screen equipment. This product has the characteristics of large screening output and high screening efficiency. It is widely used in various starch screening and powder materials screening and removal of impurities. The following is a specific introduction to the glucose powder rotary vibrating screen.

Product Description

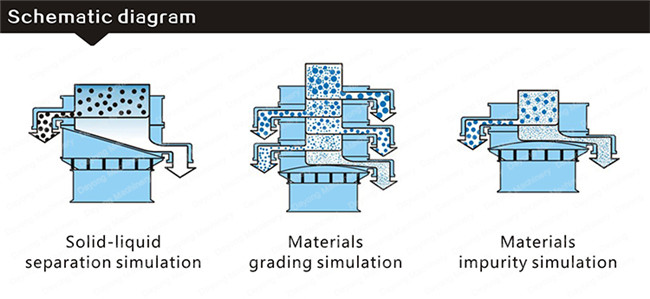

The stainless steel circular vibrating screen is a small screening equipment. Because of its circular appearance, the material running on the screen surface is a rotary type, so it can also be called a three-dimensional rotary vibrating screen. The equipment looks simple and light, but it has a wide range of uses; it can be used in a single layer, mainly used for impurity removal and screening of powder or granular products; it can also be used in multiple layers to classify materials at different levels. The stainless steel circular vibrating screen is mainly used for impurity removal and screening of glucose powder. Generally, one layer of screen is enough to separate the coarse powder and fine powder in the glucose powder. Because glucose belongs to the pharmaceutical industry, the sanitary requirements are quite strict. The vibrating screen must also meet the sanitary standards of the pharmaceutical industry, with internal and external polishing, and no dead ends.

Working Principle

The glucose powder rotary vibrating sieve changes the trajectory of the glucose powder on the screen by changing the phase angle of the unbalanced weights at the upper and lower ends of the vertical vibrating motor, so that the glucose powder performs horizontal, vertical, and inclined three-dimensional motion on the screen. Then achieve the purpose of screening.

1. High screening precision and high efficiency, applicable to any powder, granule and mucus.

2. The welding parts have no dead corners, and they are easy to clean and disinfect thoroughly.

3. DY series rotary vibrating screen adopts a new type of grid structure, the screen has a long service life, and it only takes 3-5 minutes to change the screen.

4. The whole machine can be used with single-layer and multi-layer screens.

5. The resin vibrating screen is small in size, does not occupy space, and is easy to move. The outlet can be adjusted at 360 degrees.

6. The contact part between the screen frame and the material is made of stainless steel.

7. The screened materials are automatically discharged and can be operated continuously.

8. The upper part of the sieve machine is a fully enclosed dust structure, dust does not fly, liquid does not leak, the screen does not block, the sieving can reach 500 meshes, and the filtration can reach 5μm.

(Live chat)

(Live chat)

_213x160.jpg)

+86-373-3669005

+86-373-3669005 sale@dyvibratingscreen.com

sale@dyvibratingscreen.com +86-373-3669006

+86-373-3669006 From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).

From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland). Your Position:

Your Position:.jpg)

_600x642.jpg)