The rotary vibrating screen is a customizable machine, which can be manufactured as the customers' different needs.

Attention2:

The rotary vibrating screen also be called as other name in different country, for example, sometimes will also named it as rotating vibrtory separator; round separator; vibro screen; circular screen separator; gyro sifter; gyro screen; Round Vibrating Sifter; Round Type Vibrating Screen Separator; vibratory sieve; vibro Shifter; vibro sifter and so on.

Distinctive Features:

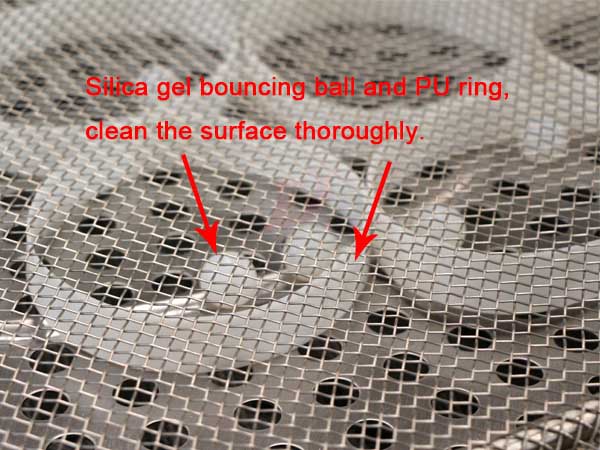

2. Silica gel bouncing ball and PU ring:

We adopts the silica gel bouncing ball and PU ring beneath every screen surface to clean it.

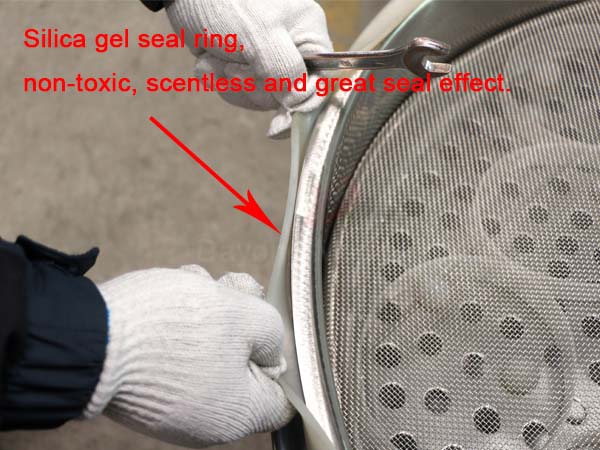

3. Silica gel seal ring:

The silica gel ring has a great sealing effect between every two decks.

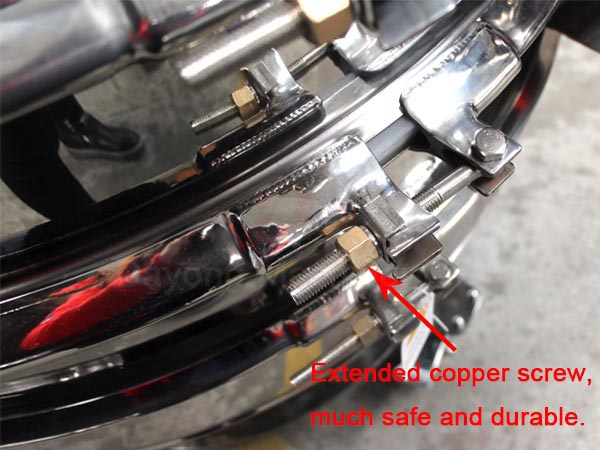

4. Extended copper screw:

We adopts extended copper scrw on every clamp, much safe and durable.

5. Protective cover:

We could add a extra cover around the springs to ensure fully enclosed and beautiful appearance.

Related equipment:

| Type | Power(KW) | Diameter of screen(mm) | volume(mm) | Layer |

| DY-400-1S DY-400-2S DY-400-3S |

0.18 | 320 | 580*580*560 580*580*660 580*580*760 |

1 2 3 |

| DY-600-1S DY-600-2S DY-600-3S |

0.55 | 550 | 800*800*680 800*800*780 800*800*880 |

1 2 3 |

| DY-800-1S DY-800-2S DY-800-3S |

0.75 | 750 | 900*900*780 900*900*930 900*900*1080 |

1 2 3 |

| DY-1000-1S DY-1000-2S DY-1000-3S |

1.5 | 950 | 1160*1160*880 1160*1160*1030 1160*1160*1180 |

1 2 3 |

| DY-1200-1S DY-1200-2S DY-1200-3S |

1.75 | 1150 | 1360*1360*980 1360*1360*1160 1360*1360*1360 |

1 2 3 |

| DY-1500-1S DY-1500-2S DY-1500-3S |

2.2 | 1450 | 1850*1850*1130 1850*1850*1330 1850*1850*1550 |

1 2 3 |

| DY-1800-1S DY-1800-2S DY-1800-3S |

3 | 1750 | 2200*2200*1360 2200*2200*1460 2200*2200*1680 |

1 2 3 |

Your Position:

Your Position:

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(Live chat)

(Live chat)

_213x160.jpg)

+86-373-3669005

+86-373-3669005 sale@dyvibratingscreen.com

sale@dyvibratingscreen.com +86-373-3669006

+86-373-3669006 From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).

From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).