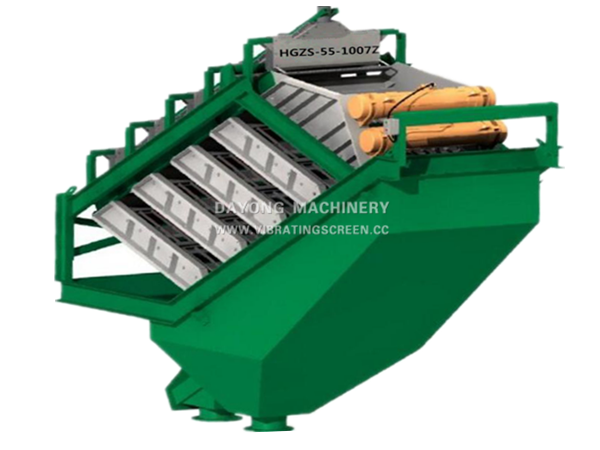

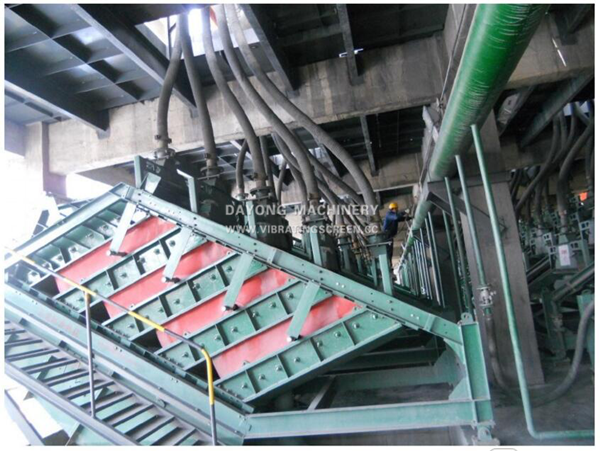

High frequency stack sieve is a special product of DAYONG company. With the principle of double degree of freedom resonance, the single vibration source (vibration motor group) is designed to realize the compound vibration of the whole machine linear vibration and exciter knocking screen. Vibration parameters can be controlled by frequency conversion. The vibration way of this equipment is unique, saving energy, high screening efficiency, large processing capacity, advanced technology, simple structure, stable and reliable operation, is the field of fine-grained material screening one of the most advanced equipment.

|

Model |

Vibration frequency(r/min) |

Particle size(mm) |

Capacity |

Power(kw) |

Screening area(㎡) |

Overall size(mm) |

|

HGZS-33-1007Z |

1500 |

0.043-6.0 |

30-120 |

4.5 |

4.41 |

4050×1510×3530 |

|

HGZS-44-1007Z |

1500 |

0.043-6.0 |

40-150 |

4.5 |

5.88 |

5019×1510×3889 |

|

HGZS-55-1007Z |

1500 |

0.043-6.0 |

50-200 |

4.5 |

7.35 |

5640×1510×4204 |

|

HGZS-33-1207Z |

1500 |

0.043-6.0 |

35-130 |

4.5 |

5.25 |

4573×1803×3560 |

|

HGZS-33-1207Z |

1500 |

0.043-6.0 |

45-150 |

4.5 |

7.9 |

5402×1803×3562 |

|

HGZS-44-1207Z |

1500 |

0.043-6.0 |

45-180 |

4.5 |

7.03 |

5193×1803×3895 |

|

HGZS-44-1207Z |

1500 |

0.043-6.0 |

60-120 |

6.0 |

10.54 |

5845×1803×4015 |

|

HGZS-55-1207Z |

1500 |

0.043-6.0 |

60-220 |

4.5 |

8.88 |

5813×1803×4243 |

|

HGZS-55-1207Z |

1500 |

0.043-6.0 |

80-250 |

7.2 |

13.2 |

6747×1803×5398 |

|

HGZS-55-Z1510Z |

1500 |

0.043-6.0 |

170-250 |

3.92 |

15 |

8120×2177×7524 |

Your Position:

Your Position:

.png)

(Live chat)

(Live chat)

_213x160.jpg)

+86-373-3669005

+86-373-3669005 sale@dyvibratingscreen.com

sale@dyvibratingscreen.com +86-373-3669006

+86-373-3669006 From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).

From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).