-

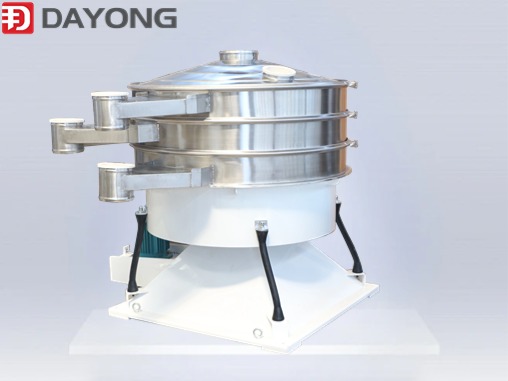

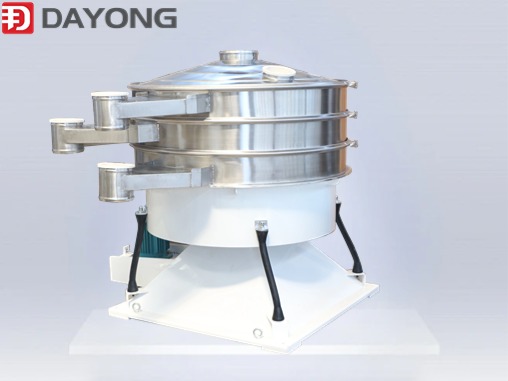

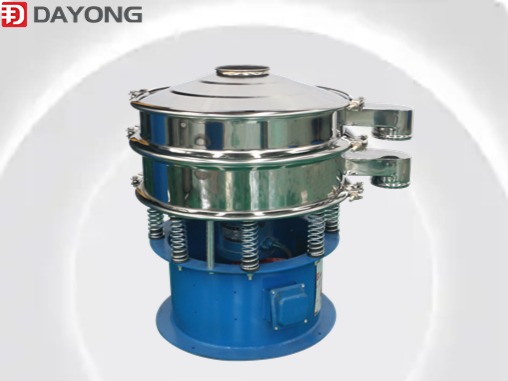

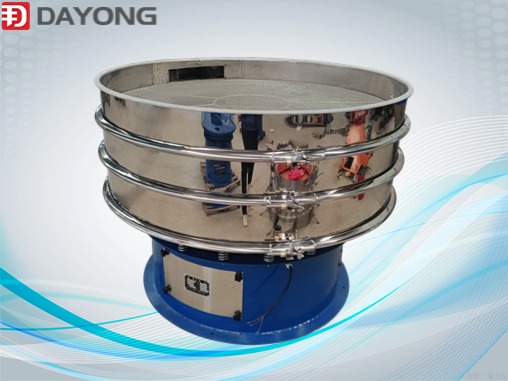

How to choose the model of rotary vibrating screen?

How to choose the model of rotary vibrating screen?

The vibration screen model of Xinxiang Dayong Machinery can be selected based on factors such as materials, processing capacity, and on-site space.

-

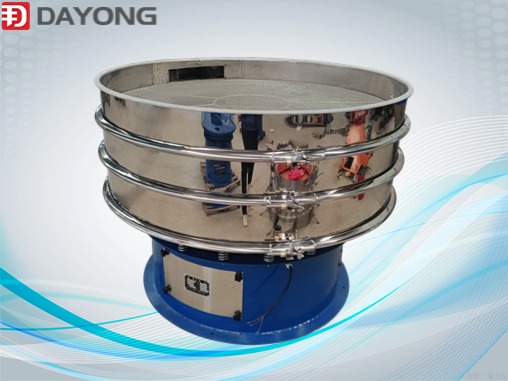

.jpg) How to use the rotary vibrating screen correctly?

How to use the rotary vibrating screen correctly?

The Xinxiang Dayong rotary vibrating screen has the advantages of small size, no space occupation, high screening accuracy, simple operation, and convenient screen replacement. We should use it correctly.

-

Does the screening of oatmeal powder require an ultrasonic vibrating screen?

Does the screening of oatmeal powder require an ultrasonic vibrating screen?

Q: Does screening 220-mesh oatmeal powder need an ultrasonic system? A: Yes. Three reasons: fine powder easily agglomerates, blocking the screen; ultrasonic vibrating screens prevent this, keeping material loose. They're designed for fine materials; Xinxiang Dayong's excels in this, ensuring efficient, accurate screening. Thus, an ultrasonic system is essential.

-

.jpg) How to choose the model of ultrasonic vibrating screen?

How to choose the model of ultrasonic vibrating screen?

When choosing an ultrasonic vibrating screen model, multiple factors need to be considered comprehensively. Xinxiang Dayong Vibration Equipment Co., Ltd. provides you with some suggestions.

-

.jpg) How can dust-free feeding stations improve work efficiency?

How can dust-free feeding stations improve work efficiency?

Dust free feeding stations are widely used and have many advantages. How to improve work efficiency during use. Xinxiang Dayong Vibration Equipment Co., Ltd. will provide you with a detailed introduction in this article.

-

.jpg) What are the precautions for dust-free feeding stations?

What are the precautions for dust-free feeding stations?

Dust free feeding stations are widely used and have many advantages. What should be noted when using it. Xinxiang Dayong Vibration Equipment Co., Ltd. will provide you with a detailed introduction in this article.

-

What are the advantages of a dust-free feeding station?

What are the advantages of a dust-free feeding station?

Dust free feeding stations are widely used and have many advantages. Xinxiang Dayong Vibration Equipment Co., Ltd. will introduce its advantages in detail in this article.

-

.jpg) What are the advantages of drum screen?

What are the advantages of drum screen?

Compared to other types of screening equipment, drum screens have the following advantages.Xinxiang Dayong Machinery will provide you with a detailed introduction to the advantages of trommel screens.

-

What are the advantages of an air flow screen?

What are the advantages of an air flow screen?

Air flow screen has achieved automation, screening accuracy, and stability,etc.. Xinxiang Dayong Machinery will provide you with a detailed introduction to its advantages.

-

What are the advantages of a square swing screen?

What are the advantages of a square swing screen?

Square swing screen is a large-scale screening equipment. Large processing capacity and high screening accuracy. Xinxiang Dayong Machinery will introduce its advantages in detail to you.

-

What are the advantages of a linear vibrating screen?

What are the advantages of a linear vibrating screen?

Linear vibrating screen is a relatively large screening equipment. Large processing capacity and high screening accuracy. Xinxiang Dayong Machinery will introduce its advantages in detail to you.

-

What are the advantages of a tumbler separator?

What are the advantages of a tumbler separator?

Circular swing screen is a type of artificial screening equipment. Xinxiang Dayong Machinery will introduce its advantages in detail to you.

-

What are the advantages of experimental screening?

What are the advantages of experimental screening?

The testl sieve has a small volume and is a specialized screening equipment for laboratory material particle size analysis. Xinxiang Dayong Machinery will introduce its advantages in detail to you.

-

What are the advantages of ultrasonic vibrating screen?

What are the advantages of ultrasonic vibrating screen?

Ultrasonic vibrating screen solves the problem of difficult screening caused by static electricity and clumping of materials. Xinxiang Dayong Machinery will introduce its advantages in detail to you.

-

What are the advantages of a screw conveyor?

What are the advantages of a screw conveyor?

Spiral conveyors are widely used. Why is it so popular? Xinxiang Dayong Machinery will provide you with a detailed introduction to its advantages.

-

What are the advantages of liquid sieves?

What are the advantages of liquid sieves?

Liquid sieves are widely used. Why is it so popular? Xinxiang Dayong Machinery will provide you with a detailed introduction to its advantages.

-

What are the advantages of bucket elevators?

What are the advantages of bucket elevators?

Bucket elevators are widely used. Why is it so popular? Xinxiang Dayong Machinery will provide you with a detailed introduction to its advantages.

-

What are the advantages of vacuum feeding machine?

What are the advantages of vacuum feeding machine?

Vacuum feeding machines are widely used. Why is it so popular? Xinxiang Dayong Machinery will provide you with a detailed introduction to its advantages.

-

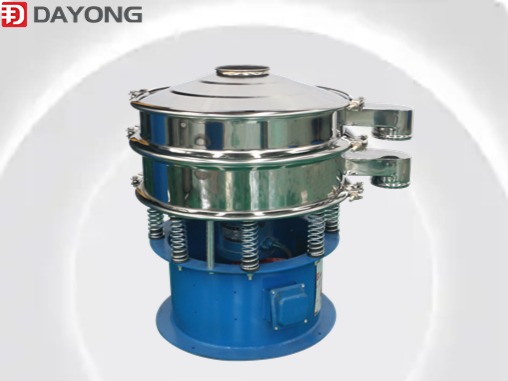

What are the advantages of rotary vibrating screen?

What are the advantages of rotary vibrating screen?

The rotary vibrating screen is widely used. Why is it so popular? Xinxiang Dayong Machinery will provide you with a detailed introduction to the advantages of rotary vibrating screens.

-

.jpg) How to improve the screening efficiency of ultrasonic vibrating screen?

How to improve the screening efficiency of ultrasonic vibrating screen?

The factors that usually affect the screening efficiency of ultrasonic vibrating screens include screen mesh, vibration motor, and material properties. Xinxiang Dayong Vibration Equipment Co., Ltd. will provide you with a detailed introduction.

-

How to improve the screening efficiency of the circular swing screen?

How to improve the screening efficiency of the circular swing screen?

The factors that usually affect the screening efficiency of a circular swing screen include the sieve mesh, vibration motor, and material properties. Xinxiang Dayong Vibration Equipment Co., Ltd. will provide you with a detailed introduction.

-

How to improve the screening efficiency of liquid sieves?

How to improve the screening efficiency of liquid sieves?

The factors that usually affect the screening efficiency of liquid sieves include sieve mesh, vibration motor, and material properties. Xinxiang Dayong Vibration Equipment Co., Ltd. will provide you with a detailed introduction.

-

How to improve the screening efficiency of linear vibrating screen?

How to improve the screening efficiency of linear vibrating screen?

The factors that usually affect the screening efficiency of a linear vibrating screen include the sieve mesh, vibration motor, and material properties. Xinxiang Dayong Vibration Equipment Co., Ltd. will provide you with a detailed introduction.

-

How to improve the screening efficiency of the rotary vibrating screen?

How to improve the screening efficiency of the rotary vibrating screen?

The factors that usually affect the screening efficiency of a rotary vibrating screen include: model, screen mesh, vibration motor etc. Xinxiang Dayong Vibration Equipment Co., Ltd. will provide you with a detailed introduction.

-

_173x129.jpg) What is the difference between circular vibrating screen and linear vibrating screen?

What is the difference between circular vibrating screen and linear vibrating screen?

Xinxiang Dayong Machinery introduces seven differences between linear vibrating screens and circular vibrating screens.

(Live chat)

(Live chat)

_213x160.jpg)

+86-373-3669005

+86-373-3669005 sale@dyvibratingscreen.com

sale@dyvibratingscreen.com +86-373-3669006

+86-373-3669006 From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).

From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland). Your Position:

Your Position:

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

_173x129.jpg)