-

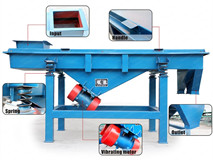

Carrot particle linear vibration separator

Carrot particle linear vibration separator

The linear screen, developed by the Xinxiang Dayong Vibration, is applied to the sieve of dry, wet and various geometrical shapes material.The series of sieve machine can be through a variety of different mesh materials,fast separation of particles, powders and liquid materials,meet a variety of production lines, especially large flow production line process configuration.

-

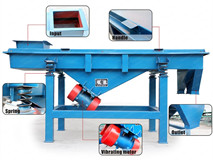

.png) Ash calcium powder linear vibrating screen

Ash calcium powder linear vibrating screen

Artificial screening of gray calcium powder has been eliminated , mainly using linear vibration.Using the heavy-duty vibrating sieve in the mining of ore, with the characteristics of large output.If the environmental requirements are more harsh , it is necessary to use a closed straight line screen ,to save ,energy and environmental protection.with the characteristics of energy saving and environmental protection.

-

Horizontal Airflow Screen in Sawdust Powder Process

Horizontal Airflow Screen in Sawdust Powder Process

Horizontal air sieve can sieve sawdust powder? This question is made by a customer who manufacture the wood-plastic flooring.

Sawdust is a kind of wood chips can be used as glass raw materials and high density board.Sawdust powder is usually mixed with debris, only the impurities will be fully removed to make the use of more raw materials, which requires vibration screening equipment. Screening sawdust usually use horizontal air sieve machine.

-

painting industry vibration screens

painting industry vibration screens

Vibrating screening equipment as the most widely used material separation machinery, has been widely used in various industries, play an increasingly important role. With the development of related materials such as coatings, vibration screening equipment in the coating production process has a very important role, the vibrating screen can be easily and effectively remove the paint may be mixed with impurities in the production process. The following analysis of paint production process in the application of vibrating screen:

-

Screw feeder in plastic particle production line

Screw feeder in plastic particle production line

Screw feeder is an efficient feeding equipment,it is the plastic processing machinery required auxiliary equipment,senting granular plastic raw materials directly into the hopper,with the automatic feeding and automatic mixing . Using all stainless steel design to ensure that contact with materials from pollution, can make the production process to achieve full automation.

-

.jpg) Linear vibration screen sieve feed volume control

Linear vibration screen sieve feed volume control

The proportion of the amount of feed and the sieving precision and the yield of the linear sieve have a certain proportion. The larger the feeding amount is, the lower the fineness of the sieving is, and the output is relatively large. Therefore, the amount of feeding and the fineness of sieving are inversely proportional, so take a variety of feeding control to achieve the best screening effect.

-

linear sieve is the most suitable for sawdust industry

linear sieve is the most suitable for sawdust industry

Sawdust mainly used for fuel and light bones filler, or composite into a man-made board, such as MDF, paper making raw materials.

Linear shaker in environmental protection, light industry, chemical applications are very common, depending on the use and field conditions, its size and screening parameters can be customized. In the sieving of sawdust, the effect of linear shaker is also very obvious, through the sieve can be made into incense or mosquito coils, consistent with the sustainable development strategy.

-

Material and screening accuracy of Medical vibration shaker

Material and screening accuracy of Medical vibration shaker

Pharmaceuticals production are closely related to the body of people, so the pharmaceutical industry production and sales requirements are very strict. Pharmaceuticals production are closely related to the body of people, so the pharmaceutical industry production and sales requirements are very strict. The role of the vibrating screen in the production of powder and liquid is to filter out the qualified particle powder and remove the unqualified particles and powder, and filter out the impurities in the liquid. The requirements of the vibrating screen for the pharmaceutical industry:

-

The Wood flour vibration separator

The Wood flour vibration separator

Speaking of powder material,it is necessary to carry out particle size screening.The wood flour vibration separator with small size, simple and reasonable structure , high precision screening, all closed without pollution, low noise, low energy consumption, easy maintenance, easy maintenance, long life and other advantages. It can be single or multi-layer use,max up to five layers.The frame is generally steel structure,but contact with the material part of the use of stainless steel if the screening corrosive materials. Motor installation can be divided into down vibration and side vibratio

-

The six major precautions for the first use of chemical linear vibrating screen

The six major precautions for the first use of chemical linear vibrating screen

Chemical linear vibrating screen widely used in chemical industry,, plastics, medicine, metallurgy, glass, building materials, food, fertilizer, abrasive, ceramics industries ,with reliable quality, large output, stable operation, simple operation, easy maintenance, fully enclosed structure, no dust and other characteristics, in the same industry be in the leading position.

-

Ultrasonic vibrating screen in the battery material industry

Ultrasonic vibrating screen in the battery material industry

The so-called battery material refers to the battery containing magnetic metal raw materials such as lead, nickel, lithium, and magnetic non-metallic materials, etc., the battery material in the whole process can not do without the vibrating screen,the battery material vibration Sieve is for these powder sieving equipment, therefore, ultrasonic vibrating screen is generally used.

-

The questions need to consider of the ultrasonic vibrating screen before running

The questions need to consider of the ultrasonic vibrating screen before running

Ultrasonic vibrating screen is a kind of high efficient and practical screening system, is designed for high strong adsorption, easy to reunite,high electrostatic, high precision, high density, light weight and other screening problem, has a superior performance! The screening accuracy can be improved by 1-70%, and the production can be increased by 0.5 to 10 times. The dry powder can be graded to 600 mesh. It is the most effective solution for mesh plug up to now. Can be widely used in pharmaceutical, metallurgical,chemical,beneficiation,food and other industry which require fine screening.Pl

-

The screening equipment for the dry powder with 600 mesh?

The screening equipment for the dry powder with 600 mesh?

Fine screening gradually in the industry get more and more attention in the industry gradually, because the final user pay more attention to the quality of the products, So how to make powder sieving much fine,get the higher product quality? Ordinary vibrating screen can solve the screening problem of ordinary materials,but for some high fineness and lightweight materials, it is easy to generate static electricity, assembling adhesion screen, causing screen blockage during screening . However,ultrasonic vibrating screen is a new kind of sieving device, which can solve this problem easily. Now

-

Characteristics Of PVC Powder Vibrating Screen

Characteristics Of PVC Powder Vibrating Screen

PVC powder particles screening and grading must be paid more attention among the many powder particles.Prior to the production of plastic products, granularity and regularization of PVC powder particle is the most fundamental prerequisite for finished plastic,so PVC powder screening and particle size grading is extremely important.

-

Pearl sand linear vibro screen

Pearl sand linear vibro screen

Pearl sand linear sieve is designed and manufactured by the China Mining Institute and our factory,below I will tell you how the linear sieve in the pearl sand industry.

-

The application of vibration filter in paper medicine industry

The application of vibration filter in paper medicine industry

1. Dry lime enters the early separation of the slurry lime pool

Purpose: to ensure the average particle size of the pulp limestone.

2. Paper filler (materials used by customers: slurry calcium carbonate and slurry titanium powder)

Objective: to improve the accuracy of papermaking filler;

-

What type of lab sieve shaker is appropriate?

What type of lab sieve shaker is appropriate?

In the process of scientific research institutions, universities, the analysis and determination of the composition of raw materials is the important data that influences the accuracy of scientific research data.Therefore, it is very important to choose which laboratory vibrating screen to screen raw materials in laboratory research equipment.Our technical personnel will explain the various situations that may appear, and help users choose the right type according to the actual usage.

-

Linear vibrating screen plays an important role in the granulation process

Linear vibrating screen plays an important role in the granulation process

Linear vibration sieve has high efficiency,replace screen quickly, high production,low energy consumption, applicable to multiple industry lines.

-

Why select ultrasonic vibrating screen for molybdenum powder sieve

Why select ultrasonic vibrating screen for molybdenum powder sieve

Molybdenum powder is an important inorganic mineral. It is mainly used in paper making, plastic, artificial rubber, food, edible color, medicine, adhesion agent and sanitary products, and its components are metal molybdenum in powder form.The ultrasonic vibrating screen of DaYong vibration production is aimed at the particularity of molybdenum powder, inhibits blocking phenomenon of adhesion, friction, flattening, wetting, etc., and improves the efficiency of screening and cleaning screen.The screening and removal of molybdenum powder are usually used in ultrasonic vibrating screen.There are m

-

Vibro screen for CMC

Vibro screen for CMC

Cellulose is extracted from the fine cotton, its usage is very wide, in food, chemicals, ceramics, handicrafts and so on. Nowhere can’t see its shadow. Known as "industrial monosodium glutamate", in different application place, the cellulose particles are not the same, soeach manufacturer has an urgent need for each manufacturer to supply refined cellulose. Of course, our vibrating screen equipment is going to solve the problem of customer screening.

-

Ultrasonic vibrating screen better for the classification of garlic powder

Ultrasonic vibrating screen better for the classification of garlic powder

With the rapid development, garlic powder is becoming a common dehydrated vegetable powder in our life, which is very popular in restaurant and household. However, the classification of garlic powder is one of most important part during the production process. Of course, Xinxiang Dayong as one vibraion sieving supplier are familiar with it , ultrasonic vibro separator can easily solve this problem.

-

How to select the most suitable vibration sieve

How to select the most suitable vibration sieve

For the irregular chemical particles, ordinary screening equipment is unable to achieve the normal screening process, then how to sort out such materials ? Dayong company propose ultrasonic tumbler screen for users in this industry. The series of sieve machine is a artificial screening action equipment, through the sieve frame shake back and forth,left and right for the effective cleaning and screening for irregular material.

-

How to install vibration table?

How to install vibration table?

1. The operator have to keep the machine pedestal level. If there are large exciting force, the operator should install the foundation bolt and tighten it.

-

Linear vibrating screen for screening dry limestone powder

Linear vibrating screen for screening dry limestone powder

Question One

Q: Which model linear vibrating screen could reach to 3t/h capacity?

A: Usually the dry limestone powder specific gravity 2.5-3.5, According to this material property, and screen size bigger than 60mesh, 1020 linear vibrating screen will reach to 3t/h.

-

Six principles of dust-remove modifying for linear vibrating screen.

Six principles of dust-remove modifying for linear vibrating screen.

1. According to the actual environment of factory, take a variety of dust-remove measures to achieve the best effect. 2. According to the actual condition, develop corresponding dust-remove equipment. The protective device should be optimized without affecting the production as far as possible.

(Live chat)

(Live chat)

_213x160.jpg)

+86-373-3669005

+86-373-3669005 sale@dyvibratingscreen.com

sale@dyvibratingscreen.com +86-373-3669006

+86-373-3669006 From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).

From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland). Your Position:

Your Position:

.png)

.jpg)