Vitamin C Ultrasonic vibration sieve

After being extracted, vitamins are made into vitamin C powder through multiple steps. Generally, powder materials need vibrating screen equipment in the production line to ensure the fineness and purity of the materials. So which type of vibration sieve for vitamin C is required? Under normal circumstances, powdered vitamin C is added to the mask, so its accuracy is extremely high. 325 mesh and even 500 mesh are common mesh screens, The specific reasons are as follows:

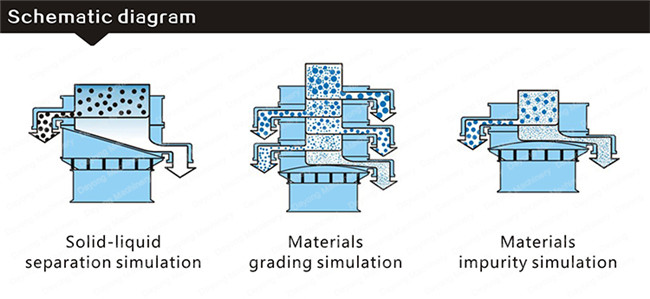

1. Ultrasonic vibrating screen has a set of ultrasonic generating device more than the ordinary rotary vibrating screen. The device is installed under the sieve frame, through which the finer materials can be screened. The materials are not only vibrated by the vibration motor, but also It is also subjected to mechanical vibration of the ultrasonic transducer, so the screening material is finer.

2. The cleaning device of the ultrasonic vibrating screen is an ultrasonic transducer. There are no accessories such as bouncing balls and pu rings, so no impurities will appear during the screening process. (As the service life of the vibrating screen increases, there will be abrasion of the bouncing ball. Some fine powder rubber will enter the finished material through the screen, but this situation does not exist in the ultrasonic vibrating screen)

3. The screening output of the ultrasonic vibrating screen is large and the power is low, which saves costs for the workshop.

(Live chat)

(Live chat)

_213x160.jpg)

+86-373-3669005

+86-373-3669005 sale@dyvibratingscreen.com

sale@dyvibratingscreen.com +86-373-3669006

+86-373-3669006 From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).

From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland). Your Position:

Your Position: