Swing Screen For Sieving Quartz

Linear screen is the most commonly used screening model, but for high-purity quartz sand, the linear screen cannot complete the fine work of its screening. Most manufacturers will choose swing screen equipment.

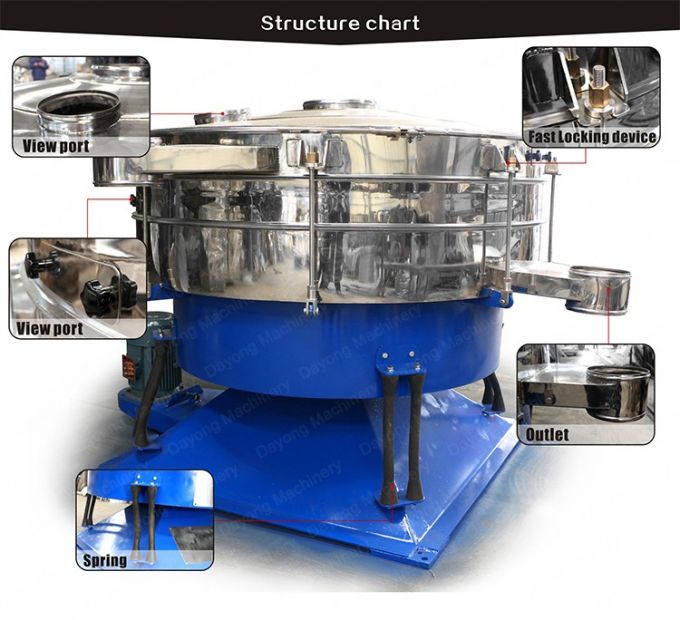

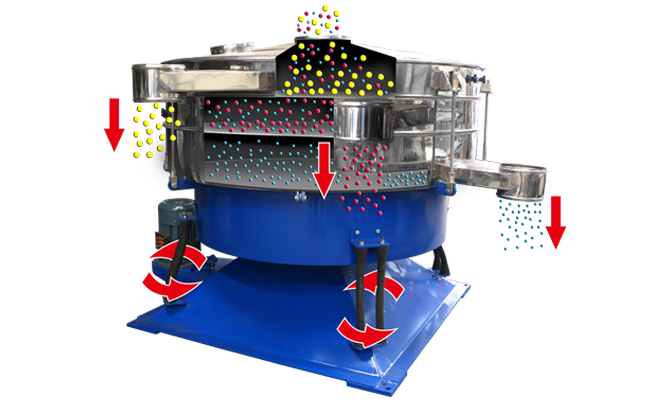

Swing screen is a kind of screening equipment closest to manual screening. It uses ordinary motor as the excitation source. The movement trajectory of the material on the screen surface is neither linear motion nor circular rotation. It has its own unique structural principle. It has the characteristics of high screening accuracy. The production capacity of the swing screen with the same floor area is 3-5 times that of the circular three-dimensional vibrating screen, so the application range is extremely wide. Swing screen equipment in the quartz stone industry has the following characteristics:

1. The swing screen can stack several layers of screen frames together, that is, one feeding can screen out materials of various specifications. This is necessary for the screening of quartz sand. As high-purity quartz sand, it is generally necessary to screen out 120 mesh and 200 mesh. And a variety of high-mesh materials such as 325 mesh, and the swing screen meets this condition.

2. One-time screening saves time and space. Various specifications can be screened at one time, which saves the idle space of the workshop and makes good use of the tight space of the workshop. One-time screening improves production efficiency.

3. The most important thing is that the swing screen has a large effective utilization area, and the screening efficiency is high per unit time. Due to the special process design, the swing screen can also screen fine materials.

(Live chat)

(Live chat)

_213x160.jpg)

+86-373-3669005

+86-373-3669005 sale@dyvibratingscreen.com

sale@dyvibratingscreen.com +86-373-3669006

+86-373-3669006 From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).

From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland). Your Position:

Your Position: